Request for Interpretation for ANSI/AGMA 2002-D19, Tooth Thickness and Backlash Measurement of Cylindrical Involute Gearing and AGMA 913-A98, Method for Specifying the Geometry of Spur and Helical Gears

Issued February 7, 2025

Question/statement:

AGMA 913-A98 section 5.5 Internal gear pair normal circular tooth thickness

AGMA 2002-D19 section 3.2.12, note 2:

Positive values of manufacturing profile shift coefficient result in thicker teeth in both external and internal gears. Negative values result in thinner teeth.

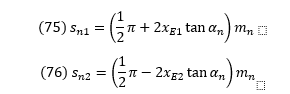

Section 4.7.5 and equations (5) and (6):

For both internal and external gears, the maximum and minimum nominal normal circular tooth thicknesses are related to the maximum and minimum manufacturing profile shift coefficients using the following relationships:

where,

sn max is nominal normal circular tooth thickness at the reference diameter, maximum, mm;

sn min is nominal normal circular tooth thickness at the reference diameter, minimum, mm;

xe max is manufacturing profile shift coefficient, maximum;

xe min is manufacturing profile shift coefficient, minimum.

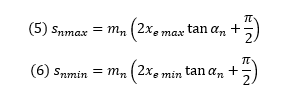

As I understand it, in equations (75) and (76) of AGMA 913-A98, sn1 is for the external pinion and sn2 is for the internal ring.

It appears that in equation (76) of AGMA 913-A98, a positive rack shift coefficient reduces the tooth thickness of an internal gear whereas in equations (5) and (6) of AGMA 2002-D19, a positive manufacturing profile shift coefficient increases the tooth thickness of an internal gear.

AGMA 2002-D19 section 3.2.12, note 2 is very clear about the effect of profile shift applying the same effect on tooth thickness for both internal and external gears (positive increases; negative decreases).

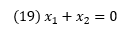

If we consider the case of an external gear pair without variation of center distance, equation (19) in AGMA 913-A98 simplifies to the following:

As a simple example, for an external gear pair with x1 = 0.5 and x2 = -0.5, the pair can operate at the reference center distance without interference because gear 2 has its tooth thickness reduced in an amount corresponding to the increase in tooth thickness in gear 1.

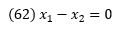

On the other hand, for profile shifted internal gear pairs without variation of center distance, equation (62) simplified to the following:

If we use a similar example, with x1 = 0.5, then for (62) to hold, x2 must be equal to 0.5 also. If we then use equations (75) and (76) to calculate the circular tooth thickness, the sum of the tooth thickness equals the circular pitch and we do not have a problem.

However, if positive profile shift coefficients increase the tooth thickness for both external and internal gears (as stated in AGMA 2002-D19 section 3.2.12, note 2), then it follows that for x1 = x2 = 0.5, the sum of the tooth thickness becomes greater than the circular pitch and the gearset cannot be assembled at the reference center distance.

Can you provide clarification on the inconsistency between equation (76) in AGMA 913-A98 and the statements and equations (5) and (6) concerning manufacturing profile shift and tooth thickness in AGMA 2002-D19?

AGMA Accuracy and Nomenclature committee response:

AGMA 2002-D19 is correct in that a positive profile shift increases tooth thickness for both external and internal gears. It corresponds to ISO 21771-1 which says:

There is a similar statement in ISO 21771 2007. The ISO standard is definitive on the subject, since the Europeans (in particular the Germans) are the ones who first (over 100 years ago) recognized and then utilized the concept. AGMA 913-A98 was written when people in the US were just trying to get an understanding of profile shift. While they got most of it right, apparently, they misinterpreted its use for internal gears.

The correct definition of profile shift sign is that moving the generating rack away from the root is a positive profile shift. Unfortunately, AGMA 913 says that moving the generating rack away from the gear center is a positive profile shift,

this is wrong. The result is the same for external gears, but not for internal gears. Consequently, the equations for internal gears are wrong. AGMA 913 uses terminology that is not currently used: What AGMA 913 calls rack shift is now called manufacturing profile shift and variable y is used rather than just xmn.