RFI 15-01 for ANSI/AGMA 2001-D04 (3), Fundamental Rating Factors and Calculation Methods for Involute Spur and Helical Gear Teeth

QUESTION: Request for interpretation/clarification of ANSI/AGMA 2001-D04 clause 18

Please clarify the meaning of the Reliability Factor Kr in paragraph 18 of AGMA 2001? Specifically, I am trying to understand whether a Kr = 1.0 correlates to fewer than 1 failure in 100 over the calculated life for each individual tooth or for the entire gearset (inclusive of all teeth in the meshing set). This question arose in an effort to estimate reliability and Mean Time Between Failure of an assembly with multiple gear meshes. If the reliability is meant to be for an individual tooth then it would mean the overall reliability for the mesh is much lower.

RESOLUTION:

ANSI / AGMA 2001 D04 clause 18 is as follows:

- 18 Reliability factor, KR

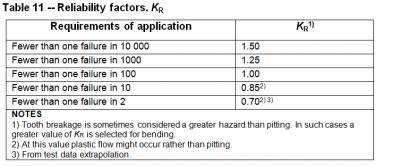

The reliability factors account for the effect of the normal statistical distribution of failures found in materials testing. The allowable stress numbers given in tables 3 through 6 are based upon a statistical probability of one failure in 100 at 107 cycles. Table 11 contains reliability factors which may be used to modify these allowable stresses to change that probability. Other values may be used if specific data is available.

When strength rating is based on yield strength, say, the values of Ky from 16.4 should be used instead of KR.

NOTES

Tooth breakage is sometimes considered a greater hazard than pitting. In such cases a greater value of KR is selected for bending.

At this value plastic flow might occur rather than pitting.

From test data extrapolation.

The AGMA Helical Gear Rating discussed the above question and reviewed the text in clause 18 of the standard. They observed the following:

- If a gear tooth has failed due to pitting or bending fatigue, the gear set consisting of a pinion and a gear has failed. The standard calculates the weakest link in the chain. When a link has failed, the chain has failed.

- It does not matter if tooth A or tooth Z has failed since once a tooth has failed, the gear set has failed.

- The phrase Fewer than one failure in X refers to a gear set consisting of a pinion and gear, and not individual teeth.

- KR is modifying the allowable stress numbers for statistical material variation of the pinion and the gear.

- If there are multiple stages in an enclosed drive, each stage can have different expectations of failure rates and KR values. The KR value for the drive is the lowest of the KR values of the individual gear sets.