Course Description

Format: Live Online Virtual Training

Date: Sept 16-18 & 23-25, 2025

(all times are ET)

- Tuesday, Sept. 16 – 12:00am-4:00pm

- Wednesday, Sept.17 – 12:00am-4:00pm

- Thursday, Sept. 18 – 12:00am-4:00pm

- Tuesday, Sept. 23 – 12:00am-4:00pm

- Wednesday, Sept. 24 – 12:00am-4:00pm

- Thursday, Sept. 25 – 12:00am-4:00pm

Reg. Deadline: September 2, 2025

Detailed Gear Design

There is a distinct difference between “designing” a gear and “optimizing” a gear design. In this course, we will address the optimization process via an understanding of those factors beyond basic banding and pitting ratings. Optimization may focus on load capacity, economy of production or minimization of overall gear system envelope. In this course we will learn how to improve gear designs via optimization and gain new insight into concepts presented through illustrations and demonstrations. Explore all factors that go into good gear design from life cycle, load, torque, tooth, optimization, and evaluating consequences.

It is recommended that you spend a minimum of 1 hour reading and reviewing the material each day.

How Many CEUs Will I Earn?

As an IACET-accredited provider, AGMA offers 2.0 CEUs for this class.

Learning Objectives

- Improve their gear designs

- Apply their understanding of gear rating theory and analysis methods

- Investigate differences in stress states among various surface durability failure modes

- Discuss time dependent and time independent failure modes related to tooth design

- Use computer generated graphics to examine mesh action and tooth interaction

- Discuss the concepts presented

Who Should Attend

Gear Engineers, gear designers, application engineers, people who are responsible for interpreting gear designs, technicians and managers that want to better understand all aspects of gear design.

Are you a member of the American Bearing Manufacturers Association (ABMA)? As an ABMA member, you receive discounts on all programs that AGMA offers. Email AGMA Education at education@agma.org for a complimentary promo code to receive member pricing on this course.

Registration Rates

Member Rates

First Registrant per Member Company

Early Bird*/Standard

$1,995/

$2,050

Additional Registrant per Member Company

$1,850

NON-MEMBER RATE

First Registrant per Non-Member Company

Early Bird*/Standard

$2,450/

$2,550

Additional Registrant per Non-Member Company

*Rate ends 9/23/25

$2,350

Instructors

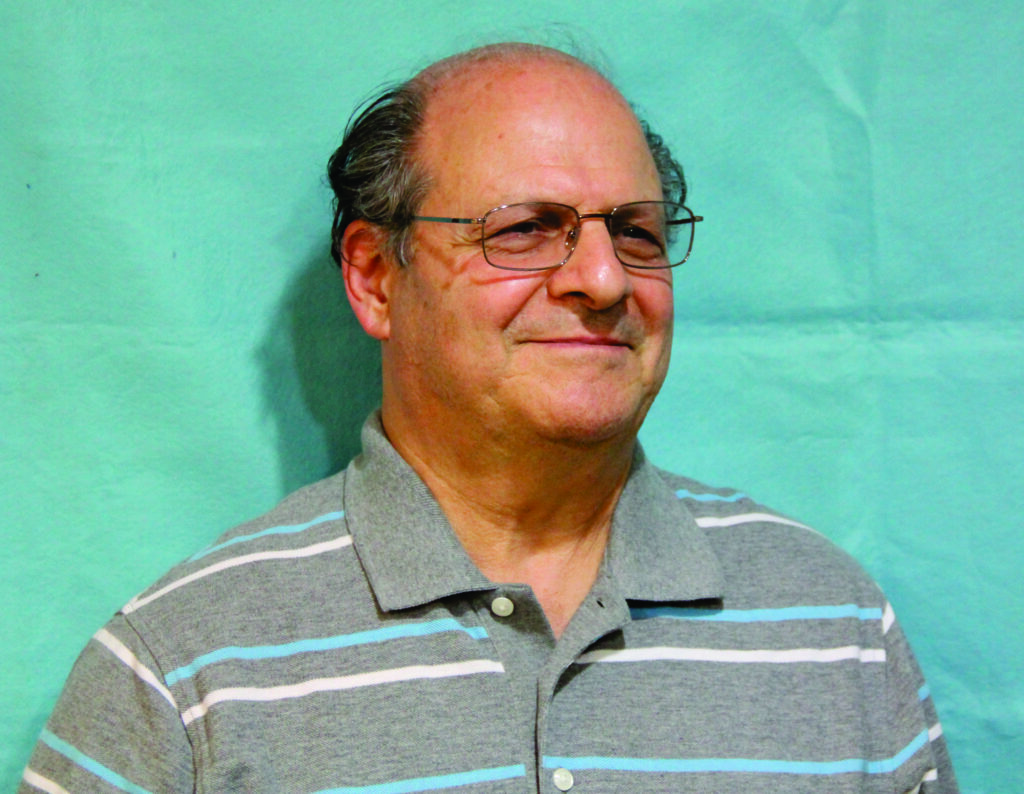

Raymond J. Drago, P.E.

Raymond J. Drago is Chief Engineer of Drive Systems Technology, Inc. (DST), a mechanical power transmission consulting organization that he founded in 1976. Mr. Drago also worked for the Boeing Company – Helicopters Division until his retirement after 37 years of service. Currently Mr. Drago is involved in the analysis, design, manufacture, assembly, and testing of many gear systems. In his role with DST, Mr. Drago is active in all areas of mechanical power transmission, including the design and analysis of drive systems in a very diverse field of application from heart pumps to very large mining & mill gears. He has used his 58 years of gear technology experience to prepare and deliver more than 150 Technical Papers and 385 courses dealing with various aspects of gear design and analysis.

I started working at Boeing in 1967 and continued until my retirement in 2004. I started Drive Systems Technology in 1976 as a part time activity while still working at Boeing (with Boeing’s knowledge and approval, under strict guidelines) which eventually grew to the point where I retired early from Boeing in order to pursue DST as a full-time activity.

Photo Release

From time-to-time AGMA uses photographs, survey answers and testimonial of AGMA events in its promotional materials. Unless this permission is revoked in writing to the AGMA, by virtue of your attendance all attendees agree to the use of their likeness in such materials.

Cancellation and Payment Policy

Please view our cancellation policy.

Please view our late registration policy.

Please view our code of conduct.