2024 Emerging Tech Webinar Series

August 7, 2024

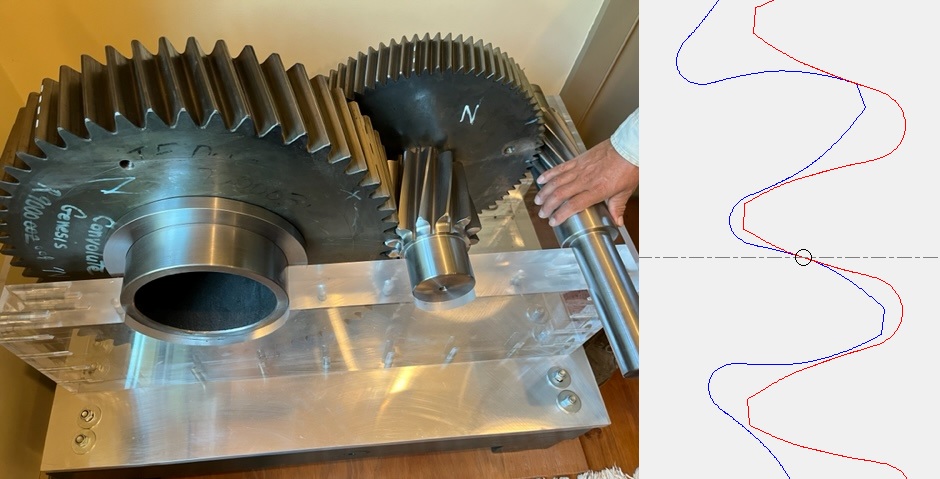

Although new developments in gear technology such as surface finishing, new materials, new coatings, and others have meaningfully contributed to increases in gear drive system power density improvements, these increases have been relatively small, that is, approximately 1% to 3% annually at best. Convoloid gearing (computer optimized) versus involute (a mechanically based system) creates incremental improvement in gear drive system power density with ranges of the order of 15% to 20% over current design practice. This webinar will detail new design and rating procedures where (2) Convoloid gear box design variants are compared to a well-established industrial gearbox (the baseline) for several critical gear rating and surface condition factor parameters resulting in power density increases of 15% to 20%. The webinar will detail design procedures and rating criteria directly compared to the involute baseline unit. A total of 11 different technical papers authored by Gear Innovations will be offered to further instruct gear design engineers in the specifics of Convoloid Gearing Technology.

Bernard Berlinger, Jr.

PResident & CEO, Gear Innovations

In 1987 Mr. Berlinger founded ASI Technologies Inc., a design and manufacturing company specializing in the production of transaxle systems for battery-powered vehicles.

It was in 1997 that Mr. Berlinger founded Gear Innovations LLC and continues to serve as its President and CEO. The company is solely a gear technology development entity. Several advancements in gear design, manufacture, and inspection technology have been developed and patented by the company. Mr. Berlinger is the named inventor, or co-inventor, of several patents all dealing with gear drive technology.

Mr. Berlinger joined the American Gear Manufacturers Association in 1962. He became Treasurer in 1984, Executive Vice President in 1985, and President in 1986. He also served as a Board Member of the AGMA Foundation.

In addition, Mr. Berlinger served on the Board of Trustees of the Gear Research Institute from 1997 to 1999 and served as its Board Chairman from 2000 to 2002. The GRI, located at the Applied Research Laboratories of Penn State University, does single client and consortium type research projects that support gear technology of the future.

Mr. Berlinger’s Bachelor of Science degree in Mechanical Engineering was from the University of Pennsylvania in 1960.

Allen J. Williston, P.E.

Certified Convoloid Engineer, Gear Innovations

Allen Williston has over 35 years of experience in the gearing industry including 16 years with an industrial gear drive manufacturer. He has been a member of AGMA since 1991 and actively involved in the Computer Programming and Enclosed Drives committees.

In 2005, as Chief Engineer of Gear Innovations, he led a multi-year comprehensive testing program jointly executed by Gear Innovations and the National Renewable Energy Laboratories (NREL) in Golden, Colorado, to test newly designed and manufactured Convoloid gearing for wind turbines with power requirements up to 440 KW (~600 HP).

Since 2009 Mr. Williston has consulted with a power transmission and wind power company in developing advanced designs involving CFD, wind tunnel experimentation, gearing, aerodynamics, electromechanical components, power electronics, and program financial feasibility.

Mr. Williston obtained his B.S. in Mechanical Engineering at the University of Missouri-Rolla and is a Professional Engineer registered in that state.

Please fill out the form below to access the webinar.